In professional collision repair, safety protocols are paramount for protecting workers, customers, and vehicle integrity. Adhering to industry regulations and implementing tailored procedures, repair teams use specialized PPE and advanced technologies like robotic welding and CAD software to mitigate risks from hazardous materials, heavy equipment, and complex modern vehicle systems. Top shops prioritize continuous improvement through staff training, robust health protocols, and wellness programs, fostering a culture where safety, skill, expertise, and employee welfare are central to delivering high-quality services.

In the fast-paced world of professional collision repair, safety is not a secondary consideration but a cornerstone. This article delves into the crucial protocols that define the industry’s standard of care. From understanding the paramount importance of safety in collision repair to exploring key measures implemented by seasoned professionals, we unravel the essence of fostering a secure work environment. Additionally, we examine strategies for continuous improvement and employee welfare, underscoring the commitment to excellence in the professional collision repair landscape.

- Understanding the Importance of Safety Protocols in Collision Repair

- Key Safety Measures Implemented by Professional Teams

- Ensuring Continuous Improvement and Employee Welfare in Collision Repair Shops

Understanding the Importance of Safety Protocols in Collision Repair

In the realm of professional collision repair, safety protocols are not mere suggestions but indispensable guidelines that safeguard both workers and customers. These protocols are designed to mitigate risks inherent in the process, which often involves handling hazardous materials, operating heavy equipment, and working with potentially dangerous tools. Adherence to safety standards not only ensures the well-being of everyone involved but also maintains the integrity of the final repair, ensuring vehicles are restored to their pre-accident condition.

The significance of these protocols cannot be overstated, especially considering the complex nature of modern vehicles. From intricate electrical systems and advanced airbag mechanisms to delicate auto glass repairs, every aspect demands precision and a thorough understanding of safety procedures. Professional collision repair teams recognize that adhering to safety best practices is not just a legal obligation but also a cornerstone of quality auto body services, fostering a culture where safety is as paramount as the skill and expertise required to perform collision repair.

Key Safety Measures Implemented by Professional Teams

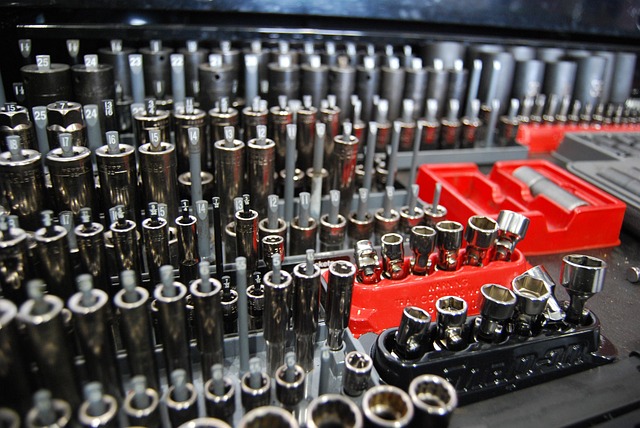

Professional collision repair teams employ a multifaceted approach to safety, prioritizing the well-being of their workers and the environment. Beyond adhering to standard industry regulations, these teams implement robust procedures tailored to the specific challenges of automotive repairs. This includes utilizing specialized personal protective equipment (PPE) like respirators, gloves, and safety goggles to shield against hazardous materials and debris during vehicle body repair processes.

Furthermore, professional auto body shops maintain a meticulous organization and cleaning regimen, ensuring that work areas are free from loose parts and contaminants that could cause accidents. They also integrate advanced technologies designed for safety, such as robotic welding systems and computer-aided design software, which enhance precision and reduce the risk of human error during complex procedures like auto glass repair.

Ensuring Continuous Improvement and Employee Welfare in Collision Repair Shops

In the dynamic landscape of professional collision repair, continuous improvement is not just a goal but an imperative. Top-tier automotive body shops invest heavily in training and updating their staff with the latest industry standards and best practices. This ensures that every team member stays current with advancements in car body repair techniques, safety protocols, and environmental considerations. By fostering a culture of learning, these shops maintain high-quality outcomes while adhering to stringent safety measures.

Employee welfare is intricately linked to the overall success of a collision repair shop. Recognizing this, leading establishments prioritize creating a safe, supportive work environment. This involves not only implementing robust health and safety protocols but also offering wellness programs, regular break periods, and adequate personal protective equipment (PPE). Such initiatives not only protect workers during tasks like car body repair but also boost morale and productivity, ultimately enhancing the overall customer experience in professional collision repair services.

In the realm of professional collision repair, prioritizing safety is not just a measure but a cornerstone. By adhering to stringent protocols, these teams ensure the well-being of their employees and the quality of their work. Through continuous improvement and investment in training, they navigate the intricate landscape of modern vehicle repairs, fostering a culture that resonates with safety, precision, and excellence. This commitment to safety not only safeguards those within the shop but also contributes to the overall reputation of the professional collision repair industry.